[ad_1]

-

Cobalt is one of the world’s most important natural resources.

-

The Democratic Republic of Congo is estimated to possess 70% of the global supply of cobalt.

-

But terrible working conditions have companies and countries looking at alternatives.

Cobalt is the new blood diamond.

It’s highly valuable and dangerous to extract. The Democratic Republic of Congo is responsible for about 70% of the world’s supply of Cobalt.

As the world transitions to renewable energies to fight climate change, the demand — and the price — for cobalt, a crucial ingredient used to make lithium batteries, has skyrocketed.

But even as the cost increases, the working conditions of the people mining it can be brutal, and the pay is almost nothing — The Guardian found in an investigation that workers were getting paid about 35 cents an hour.

Here’s the reality of where cobalt comes from and how it is mined.

In the Democratic Republic of Congo, deep craters are dug into the earth to mine cobalt, a natural resource required to make lithium batteries.

Sources: Vanity Fair, New York Times

These batteries power everyday technologies for much of the world, including mobile phones and electric car batteries.

Sources: Vanity Fair, New York Times

The DRC is the source for about 70% of the world’s cobalt supplies. It is in the unenviable position of having one of the world’s lowest GDPs while being one of the richest in natural resources.

Source: Vanity Fair

The demand for cobalt keeps growing, as does its price. In mid 2020, it was worth $29,000 per metric ton. By March 2022, it was up to $82,000 per ton. Experts agree the demand is only going to increase.

Source: Vanity Fair

Because of how valuable it has become and how terrible the working conditions often are for those mining it, cobalt is known as the “blood diamond of batteries.”

Source: New York Times

There are two forms of mining in the DRC: one is executed by corporations and is often done with modern technology.

The mine here is one of the corporate mines. It’s owned primarily by a multinational trading company called Glencore.

Source: New York Times

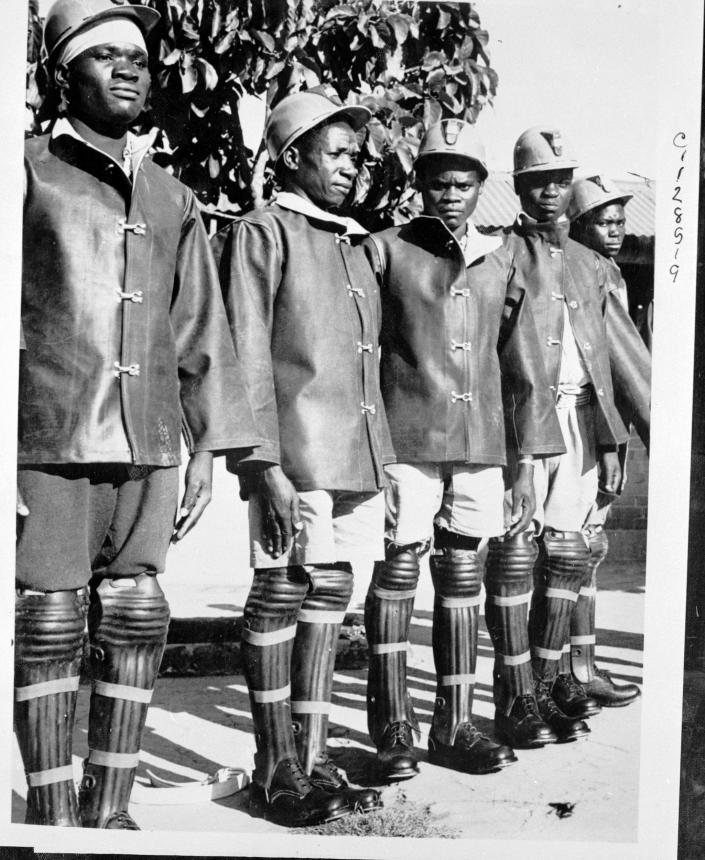

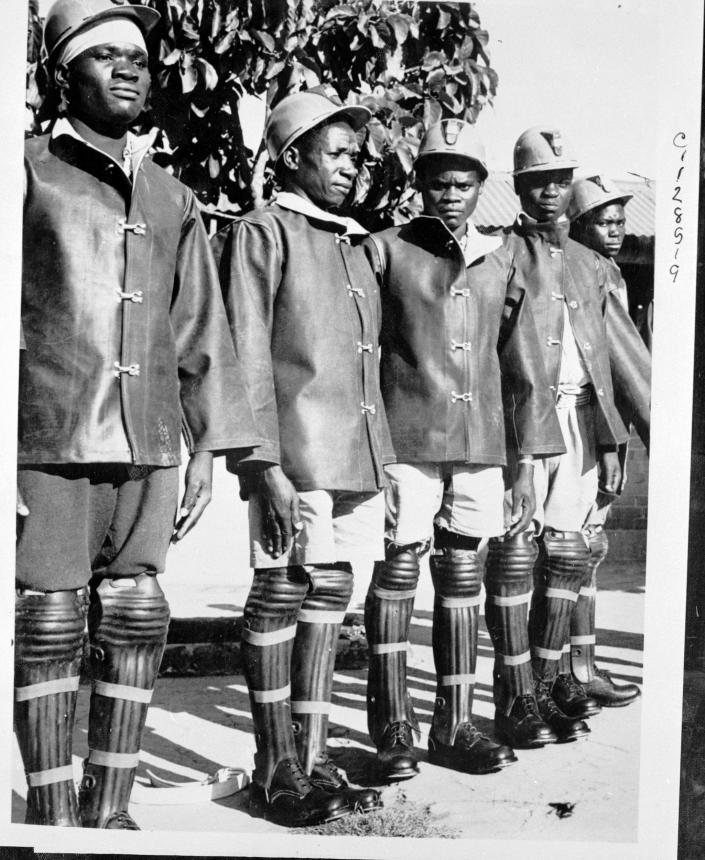

The other form, which has earned the industry its label of “blood diamond of batteries,” is known as the artisanal sector.

Source: New York Times

Here, mining is unregulated — untrained men, women, and children without protective gear basically dig around looking for cobalt.

Sources: New York Times, ABC News

There are an estimated 200,000 people in the DRC working in these mines, with another million people involved in other parts of the process.

Sources: New York Times, ABC News

Powerful countries using the DRC for its natural resources is nothing new. The DRC has been mined since the fourth century. At first, it was primarily for copper. In fact, cobalt is actually a byproduct from producing copper.

Source: New Yorker

More recently, the US used the DRC to get the uranium it required to build the atomic bombs it dropped on Japan.

Source: New York Times

Now, as much of the world attempts to fight climate change by transitioning to renewable energy, the demand for cobalt has never been higher.

Source: New York Times

Although the intention is good, it comes at a cost for those living in the DRC.

Source: New York Times

Mining cobalt is highly toxic to breathe and touch. Land near the mines suffers, too. Waterways are often contaminated, and workers are forced to touch and inhale toxic dust on a daily basis.

Source: NPR

Thousands of children are working in these mines, too.

Source: The Guardian

And there’s no quick fix. Companies and governments can’t simply decide to refuse cobalt from artisanal mines.

Source: New York Times

Due to bribery, the artisanal cobalt ends up being processed alongside the industrially mined cobalt, meaning it’s basically impossible to have a clean supply of cobalt, Harvard research fellow Siddharth Kara wrote in his investigative book, “Red Cobalt.”

Source: New York Times

And even if artisanal mines could be avoided, the working conditions in the corporate mines are often brutal, too.

According to The New York Times, there have been reports of workers repairing the insides of acid tanks without making sure it was safe first, heavy equipment being used without training and a general lack of oversight.

Sources: The Guardian, New York Times

An investigation published in 2021 by The Guardian into a mine owned by a Chinese company called China Molybdenum found that miners were being paid about $3.50 per day, or about 35 cents an hour. One miner said it was a relationship “like a slave and a master.”

Cobalt from this mine was traced to electric car companies including Volkswagen, Volvo, Tesla, Mercedes-Benz, and Renault.

Source: The Guardian

To get an idea of how much cobalt an electric car requires, you need around 10 pounds of cobalt to make a battery for a Tesla, which is over 400 times what a cell phone battery requires.

The reason cobalt is so valuable for car batteries is that it reduces overheating and the charge lasts longer.

Sources: New York Times, New York Times

There are two nations who want to control the supply of cobalt — the US and China. China already makes 75% of the world’s lithium batteries. and by all reports, looks to be winning this race.

Sources: New York Times, Politico

In the last six or seven years, China bought two of Congo’s largest cobalt mines. And as of 2020, China owned or was connected to 15 cobalt mines in Congo. There are only 19 altogether.

Source: New York Times

In December, two months after the US Department of Labor added lithium batteries to its list of child-labor related goods, the US signed a memorandum of understanding with the DRC and Zambia to help the two countries develop a new electric vehicle supply chain.

Sources: Bloomberg Law, New York Times, ABC News

Even so, some companies are looking at alternatives. For instance, Ford is looking into recycling batteries as well as developing cobalt substitutes.

Source: New York Times

Some billionaires, including Bill Gates, Michael Bloomberg, and Jeff Bezos, are funding research to explore the viability of mining in Greenland now that global warming has melted ice around the country making it more accessible.

Source: CNN

Regardless, things need to change. “We shouldn’t be transitioning to the use of electric vehicles at the cost of the people and environment of one of the most downtrodden and impoverished corners of the world,” Kara told NPR.

“The bottom of the supply chain, where almost all the world’s cobalt is coming from, is a horror show,” he said.

Source: NPR

Read the original article on Insider

[ad_2]

Source link